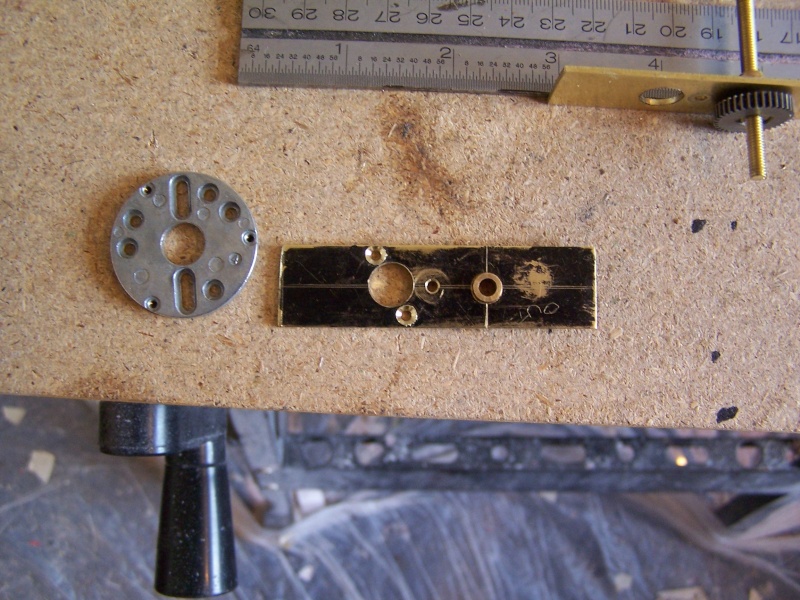

now open up the third hole in both plates to 10mm to take motor sholder.

In total there are 4 users online :: 0 Registered, 0 Hidden and 4 Guests :: 1 Bot

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Our users have posted a total of 12534 messages in 1992 subjects

We have 1021 registered users

The newest registered user is Mike Echo

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

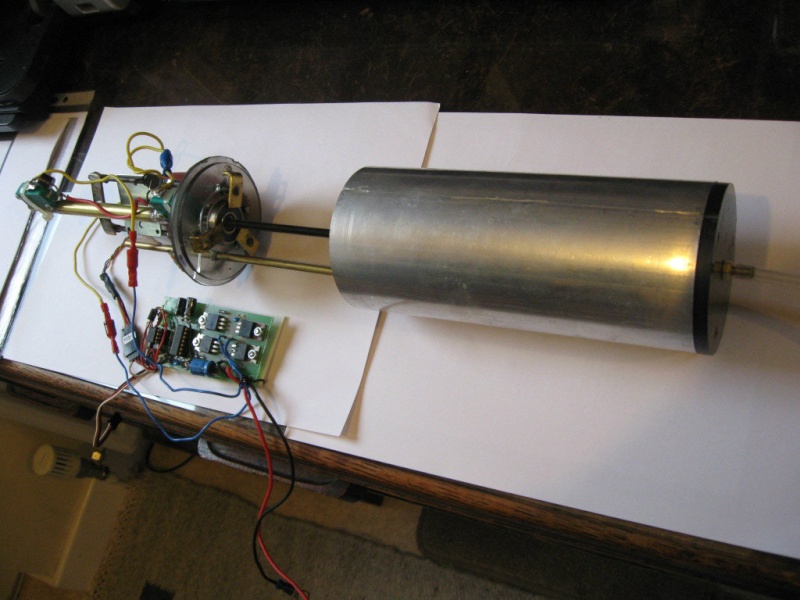

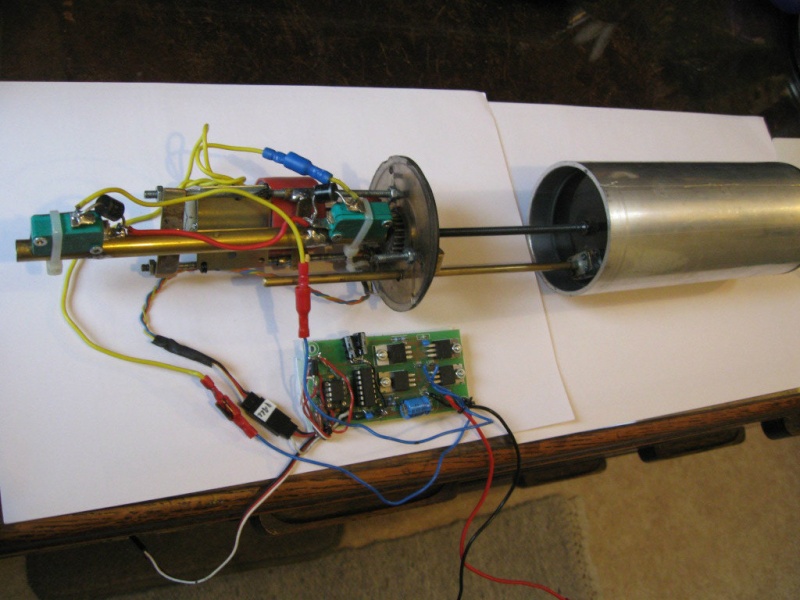

Re: Piston Ballast Systems FOR DAVID,piston tank protto

FOR DAVID,piston tank protto

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion