Who is online?

In total there are 32 users online :: 0 Registered, 0 Hidden and 32 Guests :: 1 Bot

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Latest topics

Search

Most Viewed Topics

Statistics

Our users have posted a total of 12534 messages in 1992 subjects

We have 1021 registered users

The newest registered user is Mike Echo

Similar topics

4 posters

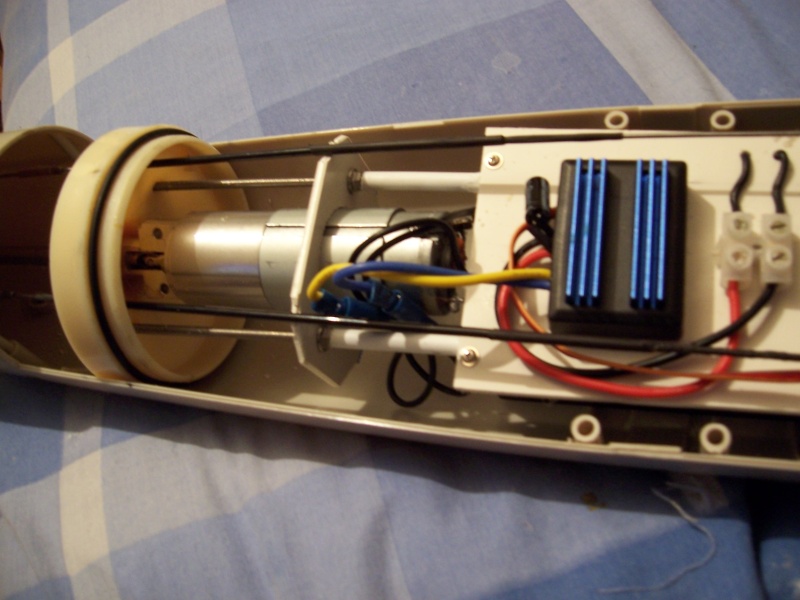

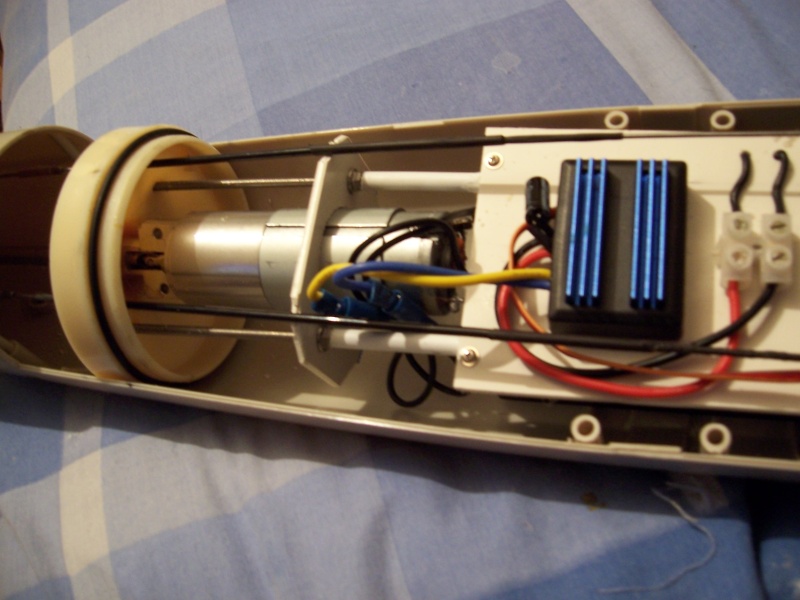

willie skipjack no2

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°1

willie skipjack no2

willie skipjack no2

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°2

Re: willie skipjack no2

Re: willie skipjack no2

That's a big cylinder...

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°3

Re: willie skipjack no2

Re: willie skipjack no2

not that big when you see the battery 2x6voltx4amp jell type takes the tube down in the water for a nice draft

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°4

Re: willie skipjack no2

Re: willie skipjack no2

Mine has a 24" long, 80mm diameter cylinder, with a water pump ballast system.

Richard

Richard

david f- AMS Treasurer

- Posts : 2412

Join date : 2010-11-10

Age : 74

Location : Cumbria

- Post n°5

Re: willie skipjack no2

Re: willie skipjack no2

Hi Willte,

Interesting photos. I think I can see why you are looking for aluminium tubing of a specific size. Is it because you are using the same commercial end caps for different submarines?

If so there is one skill/availability that would really help you with subs - Lathe access either your own or someone elses. End caps with O ring seals are not very difficult to make.

David

Interesting photos. I think I can see why you are looking for aluminium tubing of a specific size. Is it because you are using the same commercial end caps for different submarines?

If so there is one skill/availability that would really help you with subs - Lathe access either your own or someone elses. End caps with O ring seals are not very difficult to make.

David

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°6

Re: willie skipjack no2

Re: willie skipjack no2

I know DAVID if I was still working i would have made my own I am a lathe turner by trade trouble is finding a lathe in Lossie with all the places that had one are now closed all was fancy but the price for a big one and where to keep it bets me but I have this one for s mall jobs also a milling machine to fit it

mall jobs also a milling machine to fit it

mall jobs also a milling machine to fit it

mall jobs also a milling machine to fit it

david f- AMS Treasurer

- Posts : 2412

Join date : 2010-11-10

Age : 74

Location : Cumbria

- Post n°7

Re: willie skipjack no2

Re: willie skipjack no2

Yes, where to keep a lathe is a big problem for most people. I inherited my Dad's Myford lathe but had nowhere to keep it.

I now compromise with a US made Taig (Known as a Peatol in the UK) lathe which is not much bigger than yours. With riser blocks fitted (a lot of people forget about riser blocks) I can turn 110mm diameter polycarbonate without problems.

David

I now compromise with a US made Taig (Known as a Peatol in the UK) lathe which is not much bigger than yours. With riser blocks fitted (a lot of people forget about riser blocks) I can turn 110mm diameter polycarbonate without problems.

David

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°8

Re: willie skipjack no2

Re: willie skipjack no2

where do you get your blanks from david

david f- AMS Treasurer

- Posts : 2412

Join date : 2010-11-10

Age : 74

Location : Cumbria

- Post n°9

Re: willie skipjack no2

Re: willie skipjack no2

I have a large sheet of 6mm "smoked" tinted polycarbonate sheet which I found by the bins at the flat I used to live in. (I think it was probably used as a security screen somewhere. No, I didn't take it during an armed robbery!)

I bond 3 layers of this together using Plastic Weld. (Drizzle the solvent on and quickly clamp it up. Best done outside.)

Let it mature for a day and you have a good thick blank which is good for end caps.

I'm sure you can buy thick polycarbonate but it will probably be expensive. Polycarbonate is my favourite material for lots of things - incredibly tough but easy to machine. I used to to have trouble cutting it with power tools - the cut sticks back together. Following Nigel's suggestion I now use one of new generation (and quite cheap) handsaws. An 11 teeth per inch (Stanley Fat Max from B & Q) one seems to work well.

David

David

I bond 3 layers of this together using Plastic Weld. (Drizzle the solvent on and quickly clamp it up. Best done outside.)

Let it mature for a day and you have a good thick blank which is good for end caps.

I'm sure you can buy thick polycarbonate but it will probably be expensive. Polycarbonate is my favourite material for lots of things - incredibly tough but easy to machine. I used to to have trouble cutting it with power tools - the cut sticks back together. Following Nigel's suggestion I now use one of new generation (and quite cheap) handsaws. An 11 teeth per inch (Stanley Fat Max from B & Q) one seems to work well.

David

David

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°10

Re: willie skipjack no2

Re: willie skipjack no2

ever tried Vaseline when cutting it nothing sticks to it , and wipe it clean with white spirit or paint thinner

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°11

Re: willie skipjack no2

Re: willie skipjack no2

motor and gearbox

and gearbox

and gearbox

and gearbox

Tom(ADMIN)- AMS Forum Owner

- Posts : 3026

Join date : 2010-11-05

Age : 64

Location : Nevada, USA

- Post n°12

Re: willie skipjack no2

Re: willie skipjack no2

End caps by MMB?

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°13

Re: willie skipjack no2

Re: willie skipjack no2

Just a word off warning Guy's,if you want to cut poly wet just use soapy water and a course blade,don't use thiners on poly it will attack it and over time it will craze,the same applies to thread lock(loctite etc).

willte- Guest

- Posts : 119

Join date : 2013-12-15

Age : 72

Location : lossiemouth morayshire

- Post n°14

Re: willie skipjack no2

Re: willie skipjack no2

that where I got them the same type that in the sea wolf, had a look in e-bay but what a price,but £10 for two at MMB

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion