I tried contacting Mtec about how to configure the ESC (G2 Hyra15) to my Tx/Rx and to get mechanical details of tha max penetration depth for the mounting bolts, but I'm still waiting. Seems a good product byut not very good documentation or customer services.

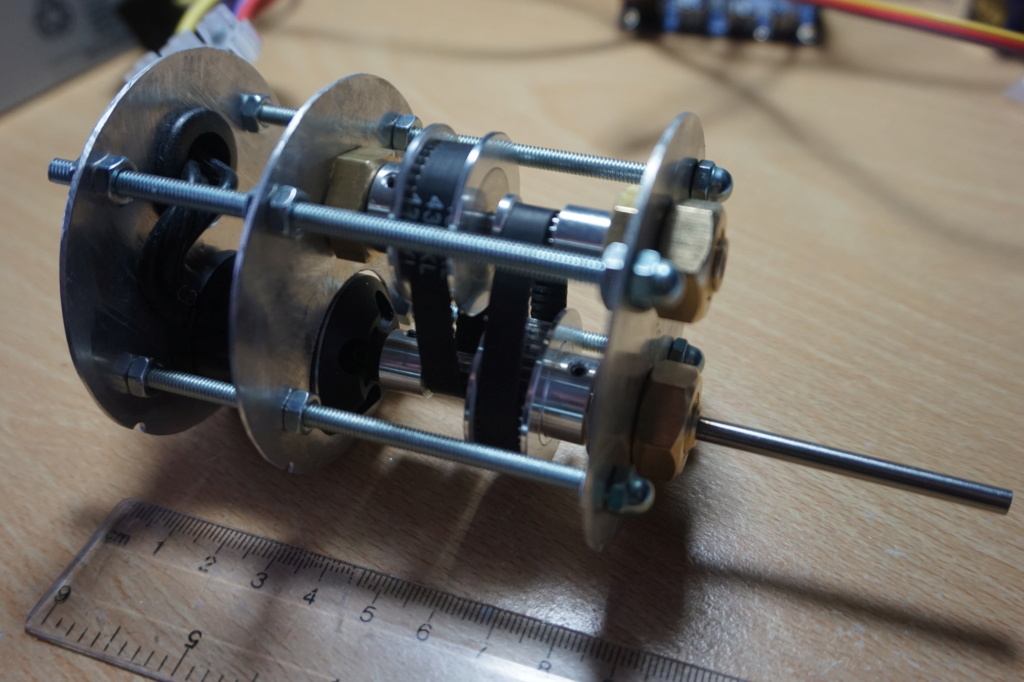

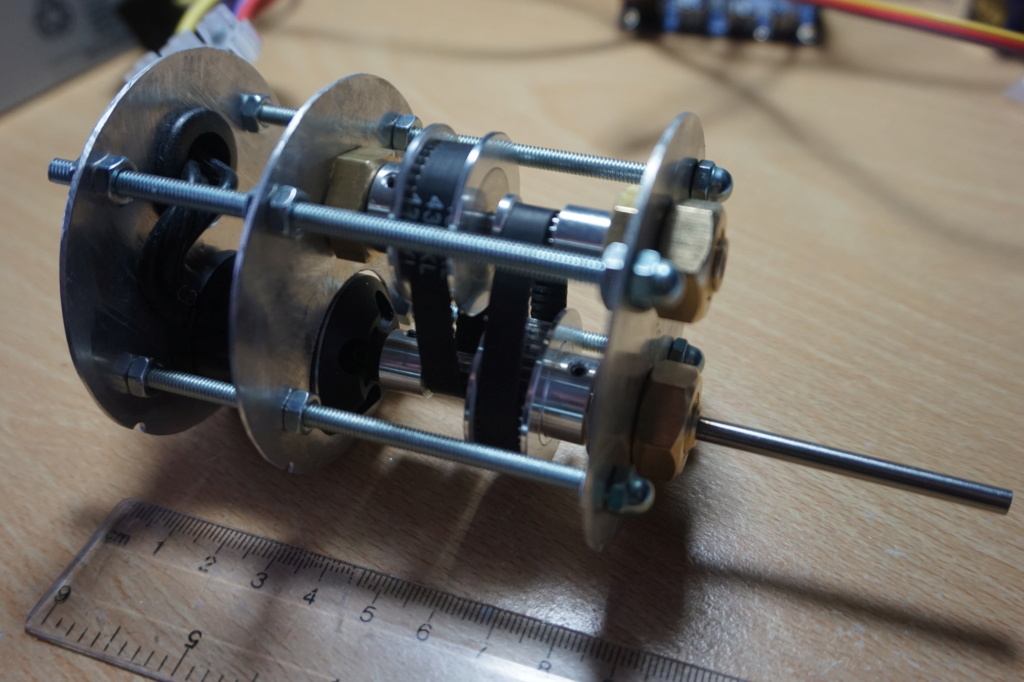

However, with the zero offset set up in the Rx software and a guess at the max bolt lengths I now have a prototype gearbox which seems to work.

Since the Hyrda15 is suppled with a 1100kv motor it should give about 12000rpm @ 12V, far more than the 1000rpm which is my aim, as that seems to be the limit of the seals I am thinking of using.

I used MXL drive belts & pulleys as they seem to be the smallest pitch (0.8"), smaller than the T2.5 (2.5mm) so smaller diameter pulleys.

I opted for a two stage design each matchng a 12-tooth with a 36-tooth to give a total of 9:1, a bit smaller than I wanted but it fits within a 68mm diameter envelope (I intend to use 75mm OD tube for the WTB). The 12-tooth was the smallest I could get bored for 4mm shaft.

The drive belts are 54-tooth (109mm) which gives a centr-centre distance of 29.5mm, though my use a plastic rule and making each frame individually means that the actual distance is more like 29mm or less; lesson - do it properly not quickly!

There are 10-tooth available but they would have required me to bore and add the grub screw.

I have pinched the idea of the bored brass bolt from this group, though at he moment they are simply plain bearings, I have yet to counter-bore to fit 8mm OD ball race bearings.

The use of tw equal stages means the motor and output shaft are concident so a bit easier to make the frames, the middle frame of course has a clearance hole for the motor as it as outrunner.

My initial thoughts are:

Use 1.5mm aluminium not 1mm, less flexing, especially the middel frame that has a large clearance hole for the motor.

Using M4 tie-bolts allows adjustment but is so fiddly to get the motor aligned, but the use of a guide block during assembly would help, or use spacer tubes. However the use of tie-bolts does allow 2 frames to be assembled and rigid then add the last.

Having 3 frames was an idea to shorten the layshaft and possibly use the space 'above' the motor for something, say a servo, but in fact I think it is too small. I think I will keep 3 frames as it provides a nice space for the motor wires to exit.

Whilst the vibration & noise is low the nuts still keep vibrating loose so I need loctite or nyloc, as I don't fancy star washers as they might upset the alignment.

Use half-nuts to retain the bearings and reduce the bolt length as they take up less space.

The max current is about 1.7A @12V max speed, though no load of course, but OK.

For the real thing the output bearing would be a longer bolt and have a seal on the outer end, but I'm not quite fixed about that yet, and of course I need the 2 control rods, again probably a drilled bolt, but not sure about bellows (simpler but longer) or O-rings (more exact maching but shorter).

The whole gearbox I intend to fix to the WTB bulkhead via the prop-shaft & control rod bolts, with the others being in recesses machined in the bulkhead. I was thinking of holding the WTB together with tie-rods outside, so lougs cast into bulkhead as there would be less penetrations to leak.

Next step is to fit ball races to the layshaft bearings and see if I can get in 2mm control rods.

Last edited by SimonH on Sat May 22, 2021 7:56 pm; edited 2 times in total (Reason for editing : add photo)

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion