The subject is this Industrial display I was commissioned to build for a vendor (Librascope/Rathion?) involved with the old Australian COLLINS class submarine program.

Ellie and I used to build such displays for industrial concerns – most of them in the defense industry – the big money always seems to follow those who support mans greatest outdoor activity. So, yes, I’m a war-monger. Sue me!

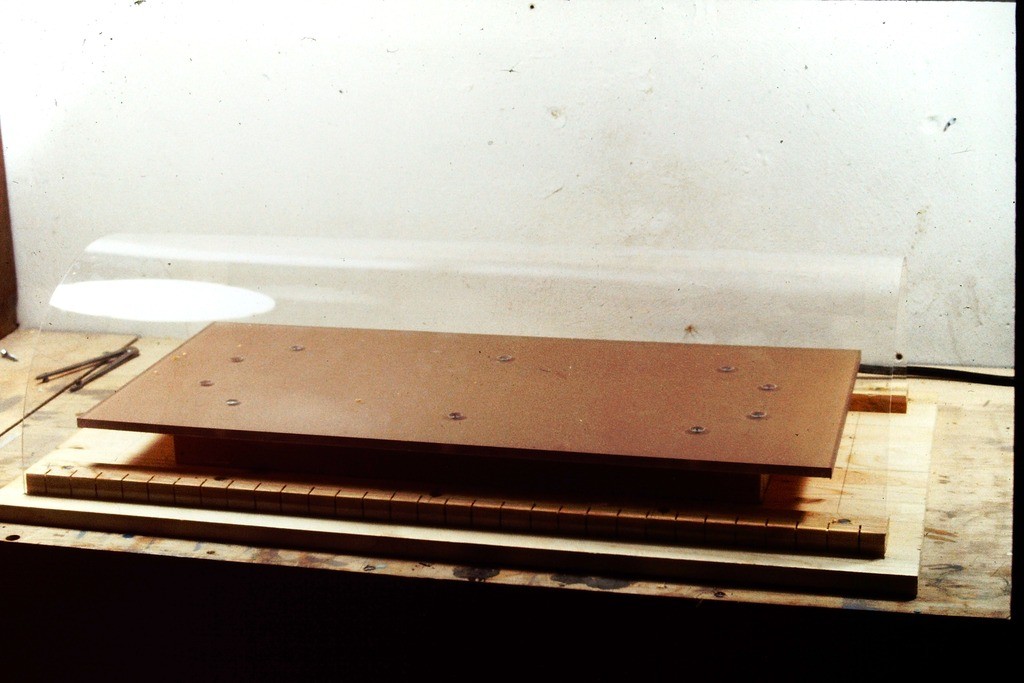

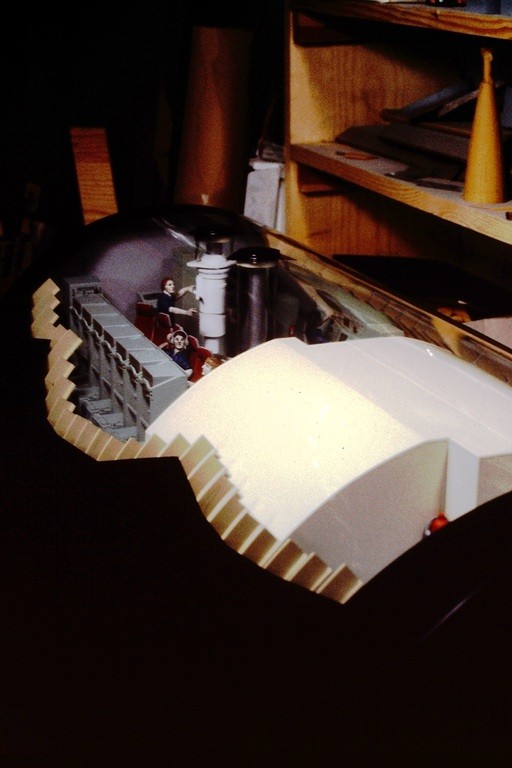

I built a 1/35 scale model of the submarines control room. The display had that area under a cylindrical portion of see-through hull. That hull formed from a sheet of Lexan plastic that was oven formed over a special bending jig.

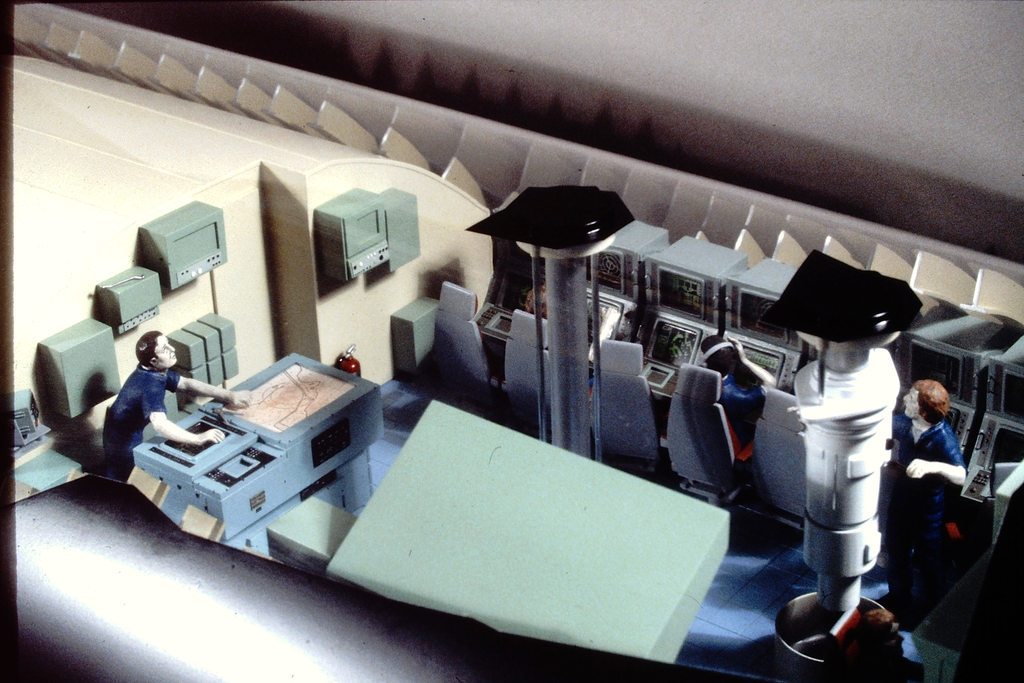

I was directed to provide crew-members at their stations and to endow them with ‘dynamic postures’ to convey a sense of purpose and drama. In addition to action poses to the figures I also back-lit most of the work-station display screens with realistic graphic presentations. (Always endeavor to deliver more than the client expects).

We provided all work-station computer displays with representative graphics (35mm slide film I processed myself) that were back-lit with flickering lights to give things that old ‘monitor’ look. I love the 555 chip … if only it could cook!

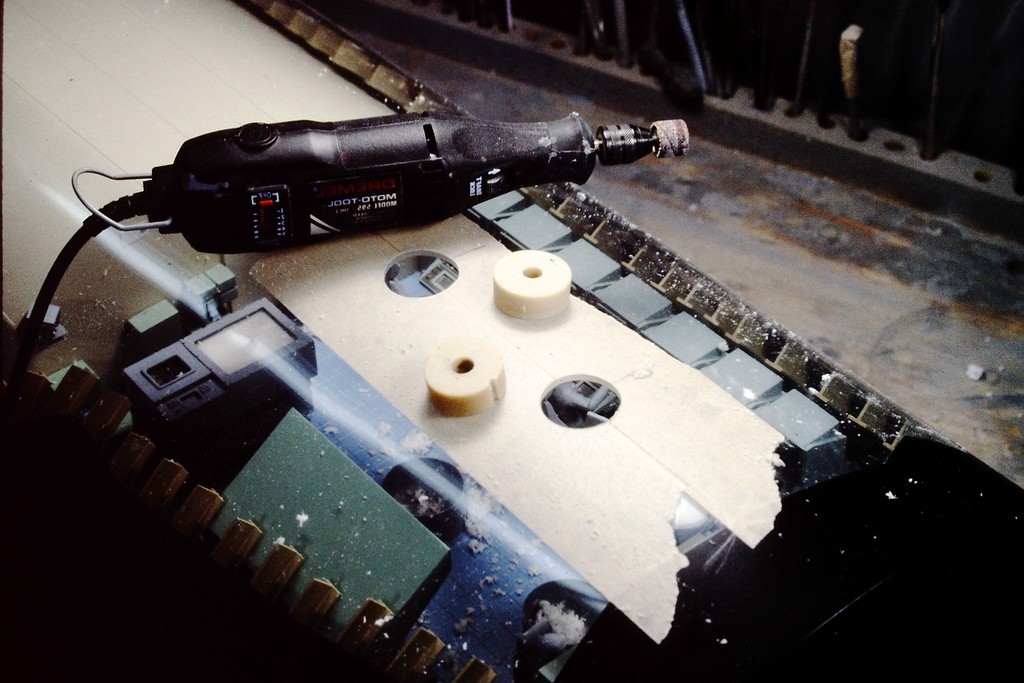

One of the virtues of Lexan I pointed out was its ability to tolerate machining. Such as these overhead periscope mounts that suspend those instruments over the open scope-wells set into the control room deck. Can’t do that with glass or Acrylic without inviting problems!

Back in the day -- when we were tied in with several defense contractors -- I rubbed shoulders with other display builders. We would entertain ourselves in a game of one-up-man’s-ship by putting in as many visual gags into a display as we could get away with without pissing off the client. Example here is the loose tools someone shoved into a space behind the sonar-radio shack area of the control room. During the show (most exhibitors kept some of us around during a show to maintain, move, fix, displays as required) exhibit makers would gather at lunch and brag about what they were able to sneak into their displays.

Another gag is that wrench atop a display over the guy at the dead-reckoning chart-table – he’s about to get bonged on the head as soon as the boat takes a significant down-angle. As it turned out, that was a step too far – the client was not amused! I had to remove it before show-time.

Lexan bonds very well to fillers, putties, primers and paints -- an important property with this type display. I had no problem hand polishing the clear Lexan to a near flawless transparent barrier between fragile display elements and probing hands.

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion