david f Fri Oct 25, 2013 3:46 pm

david f Fri Oct 25, 2013 3:46 pm

Hi Tim,

You may have a look over at the build log I'm doing on the Darnell type XXI. It may spark some ideas off.

I now have both boxes out but I'm unlikely to reinstate that tube joining the boxes. Too much leak potential! High current wires between the boxes will go via brass nuts and bolts. (See elsewhere on the forum for details) Control circuits - I haven't yet worked out the details but probably a small sealed gland.

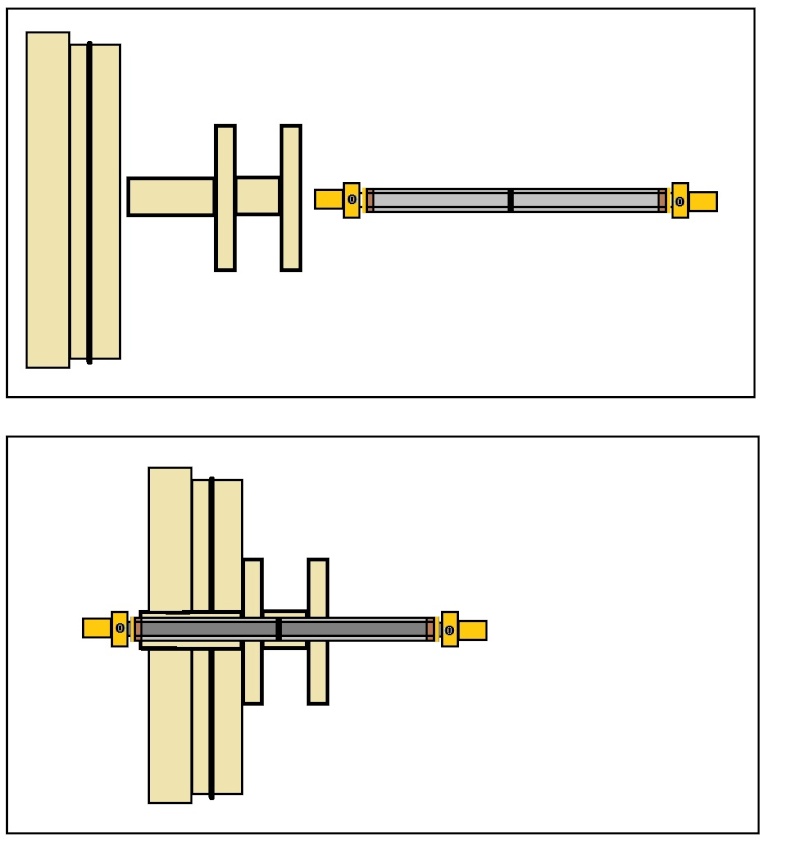

The greased prop shafts have gone but I am not using MFA motors on this one. One problem you have with them is, as you have found , you need to join shafts. That can take up valuable WTC length. Our Chairman Nigel has some neat ideas on letting MFA shafts into end caps incorporating seals. Maybe he will come in on this.

I suggest that whatever you do, you put in decent oil type seals (e.g Simrit) and have any univeral joints outside the WTC (again to save your valuable WTC length.) Don't forget that you put sealed lead acid batteries in the wet.

If you look at the build log you will see that I am testing 2 different flat plate sealing methods. Early testing seems to show that they are both working adequately. Which to choose!? A bit more testing time will tell.

David

Last edited by david f on Sat Oct 26, 2013 1:50 pm; edited 2 times in total

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion