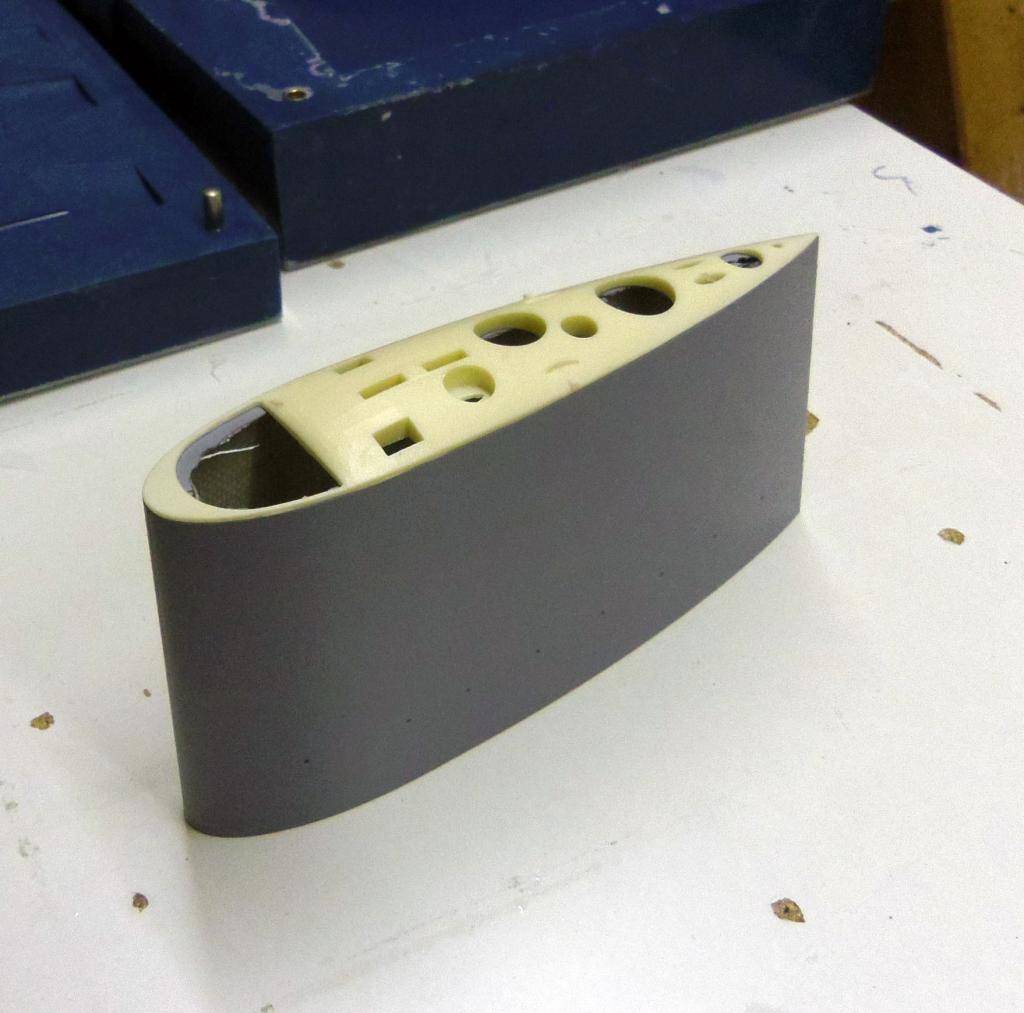

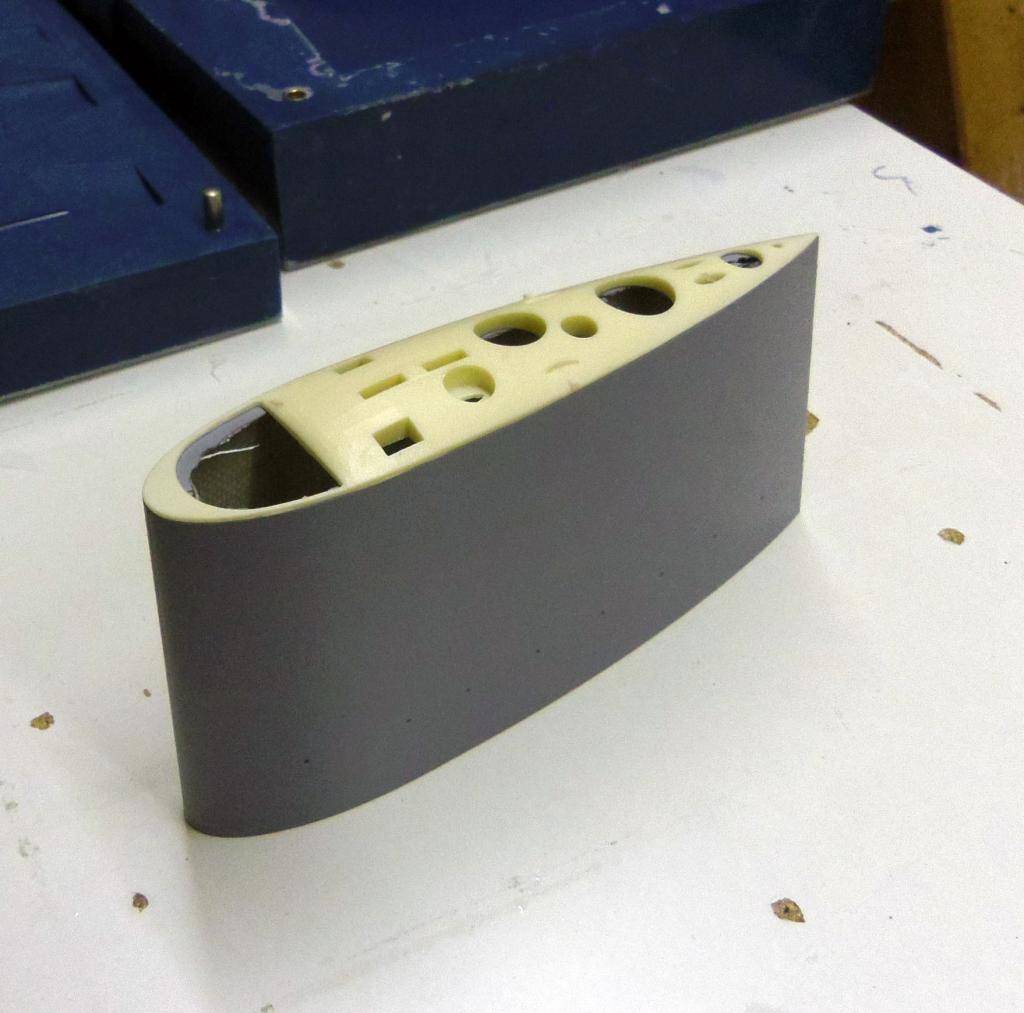

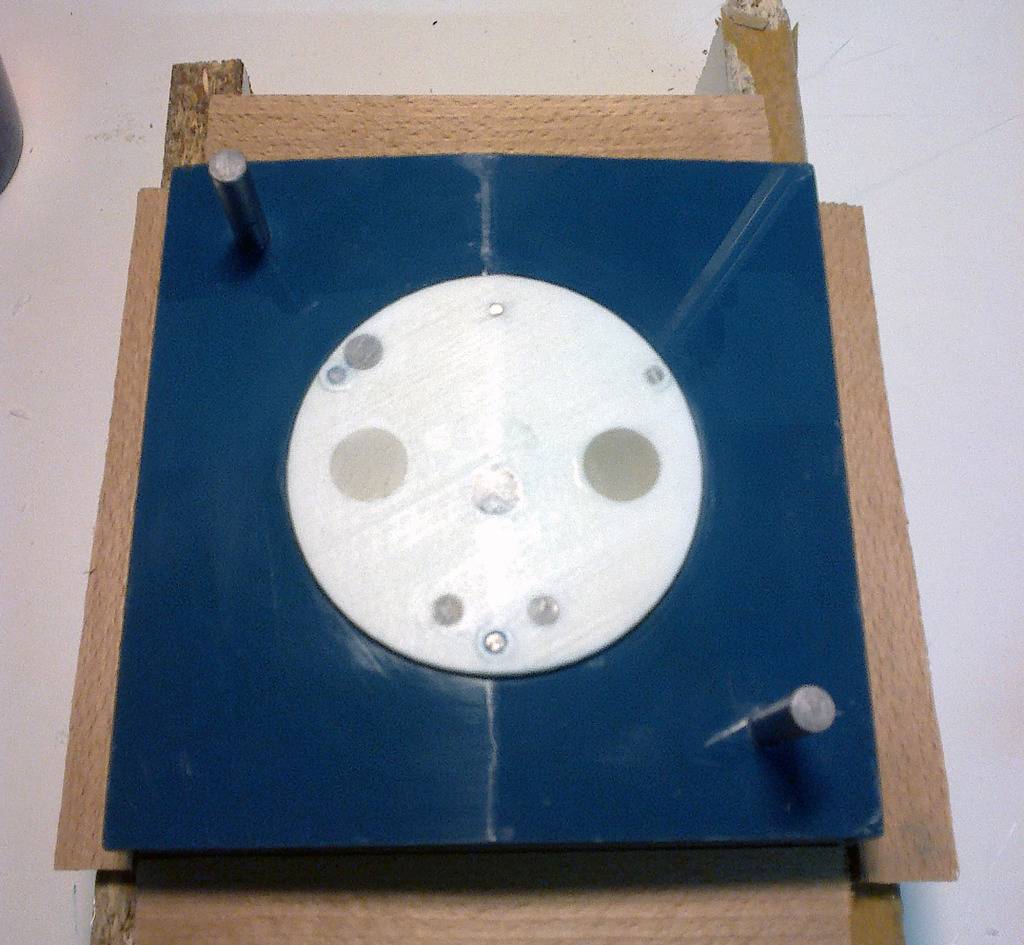

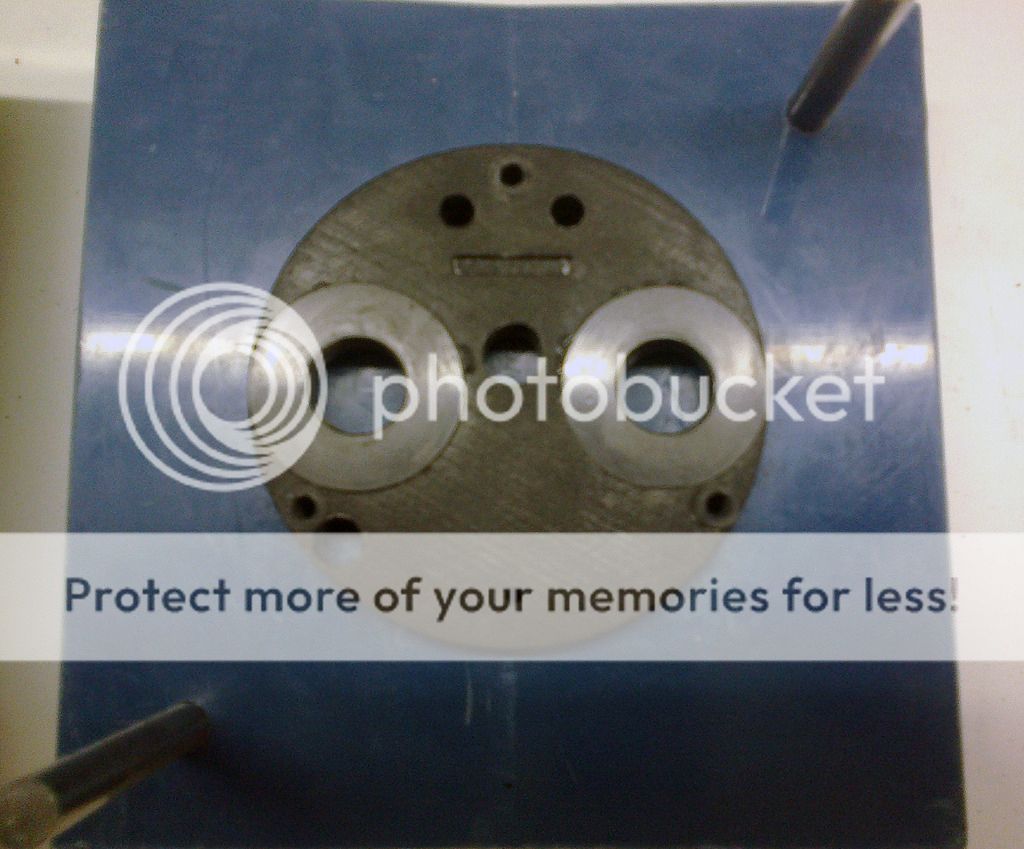

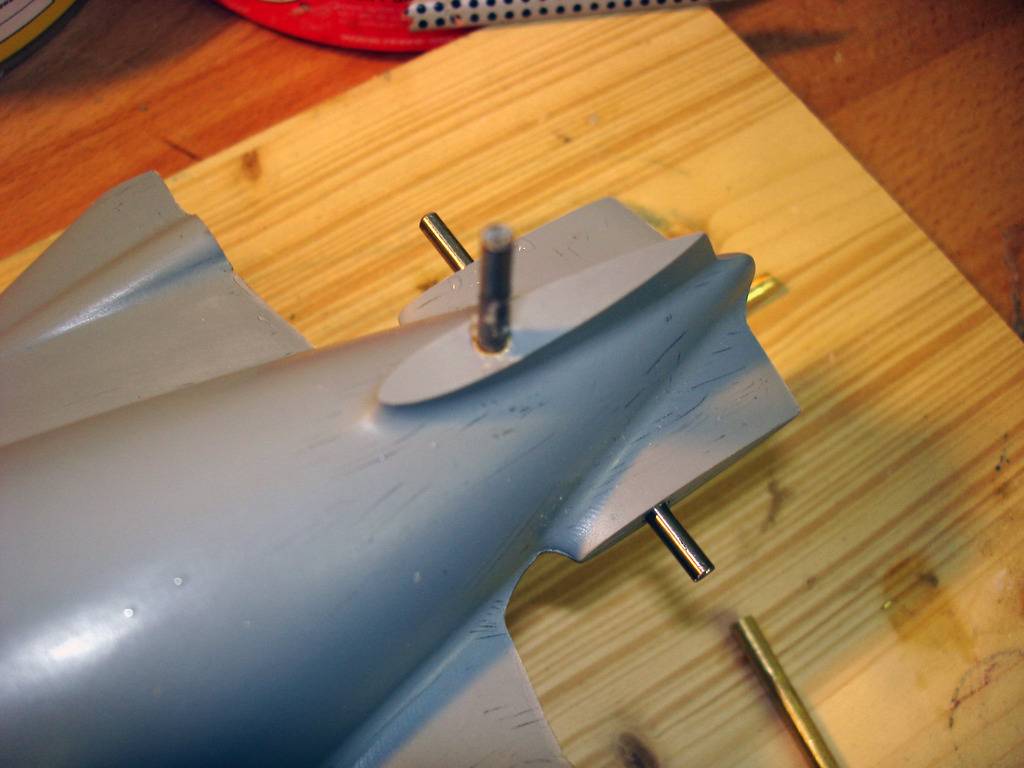

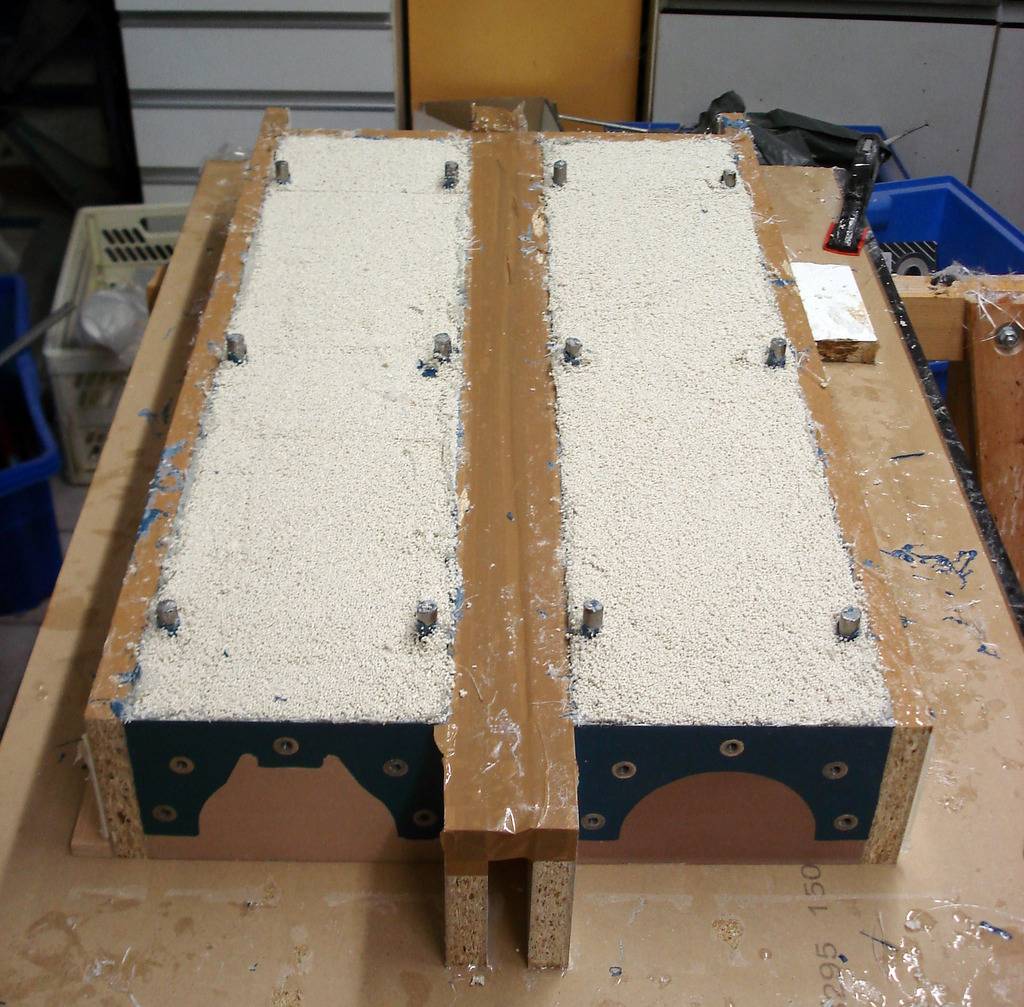

The moulds for the aft control planes are ready as well:

In total there are 2 users online :: 0 Registered, 0 Hidden and 2 Guests :: 1 Bot

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Our users have posted a total of 12534 messages in 1992 subjects

We have 1020 registered users

The newest registered user is JSAF

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus Re: New project - USS Nautilus

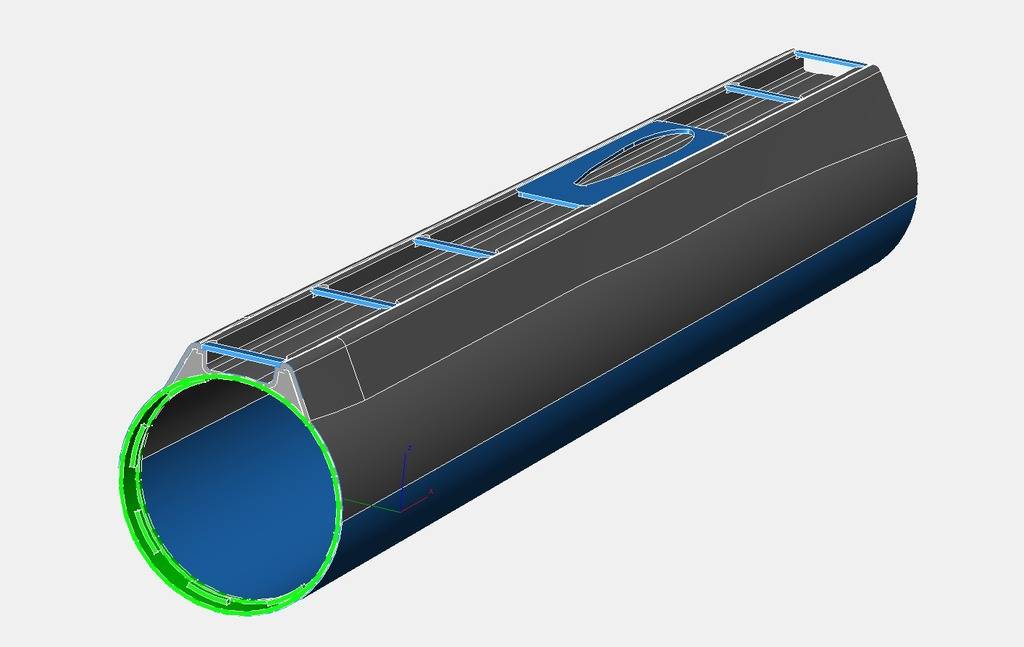

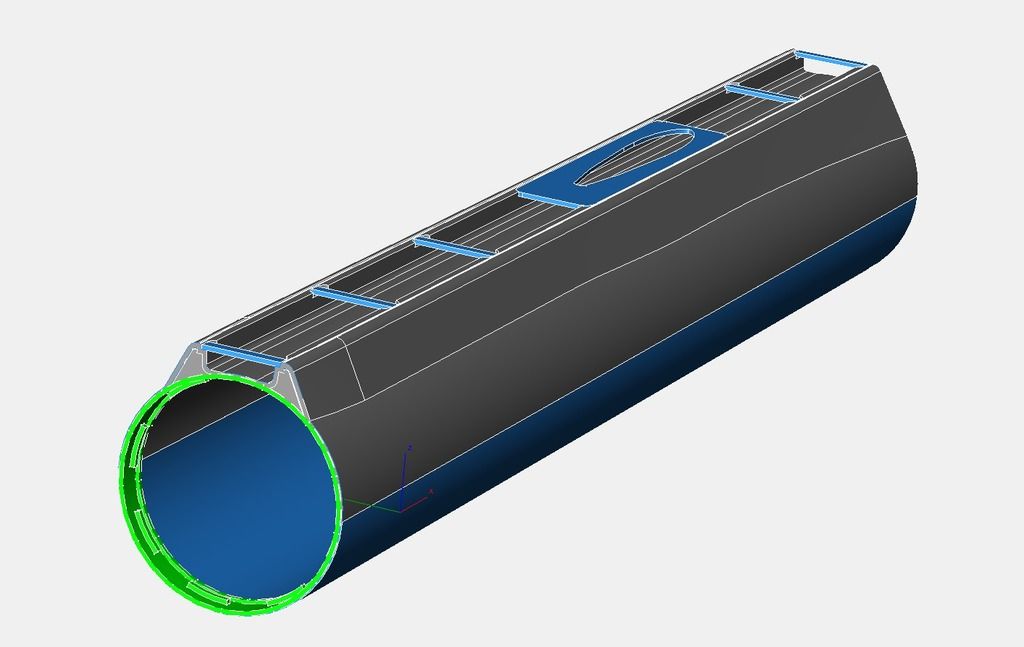

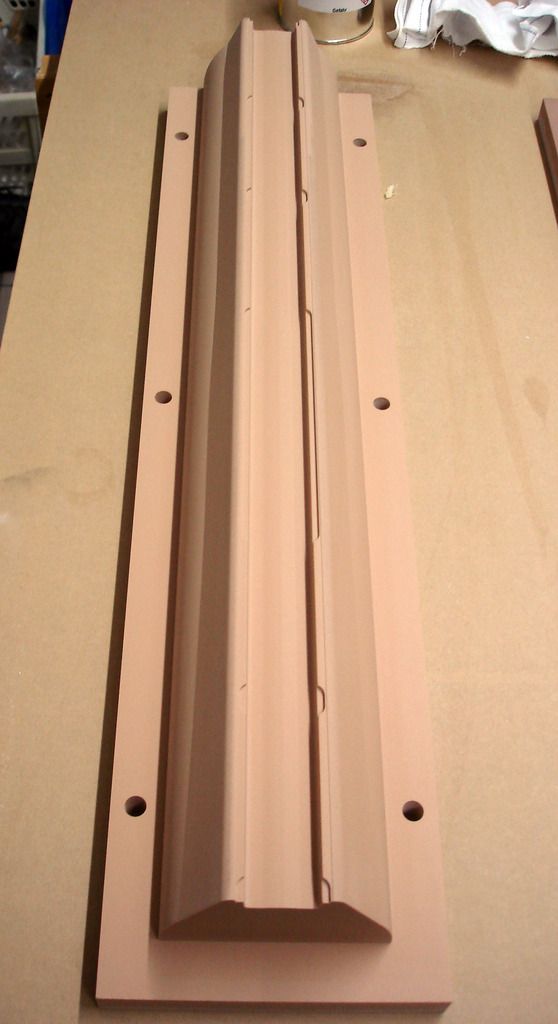

Re: New project - USS NautilusDr.Schmidt wrote:I've decided to make the watertight main section out of glass fiber, too. ...

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

Re: New project - USS Nautilus

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion