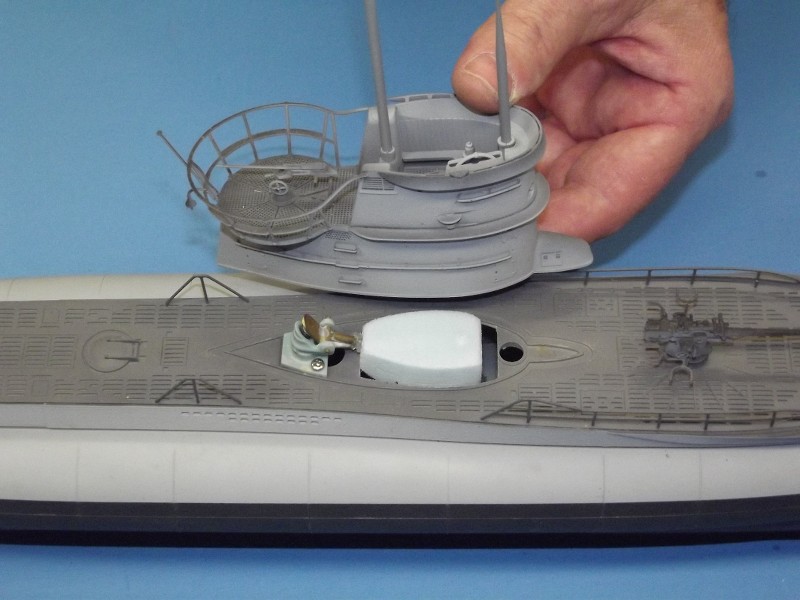

I am attempting to use a Revell 1/72 scale Type IX kit as the basis for an (initially) surface running submarine. It will have to be surface running initially as I only have 2.4 Ghz radio (model aircraft for years) and 40mHz sets seem to be 'hens teeth' currently. I read the section on LRS but lack the soldering skills (and the little grey cells) to tackle the modifications required. I looked at the Hobbyking website and couldn't find the 3.3 volt dongle that was referred to, though the tx and rx seem to be available, though I didn't think that 100mw power output was allowed in the UK.

I will use an acrylic cylinder (3mm wall thickness) as the watertight section and make the end caps using a 3d printer. Probably ABS or PETG with a O ring seal.

I will try to get working planes as well as the rudder(s) and lock them in place initially. I think that I may have to depart from scale for the rudders and aft planes as there is very little clearance and support in the stern. Possibly a single large rudder and move the planes up to a wider part of the hull to get a space with more room for support and a servo arm. Or a servo arm outside the keel through a hull bottom slot to the planes.

From reading on here I think that I will use bellows for the servo rods, though so far I haven't discovered where they come from. One of my old aircraft modelling friends said that he used to run in buggy motors in water. I know that a brushless motor will (attempt) to run in water (overturned floatplane) so I wonder if anyone on this forum has experience of running the motor in the wet section? Otherwise I suppose its another sealing problem round the prop shaft. As most surface running boats don't seem to have a leak problem I assume that standard shaft tube seal reasonably well.

I will use an acrylic cylinder (3mm wall thickness) as the watertight section and make the end caps using a 3d printer. Probably ABS or PETG with a O ring seal.

I will try to get working planes as well as the rudder(s) and lock them in place initially. I think that I may have to depart from scale for the rudders and aft planes as there is very little clearance and support in the stern. Possibly a single large rudder and move the planes up to a wider part of the hull to get a space with more room for support and a servo arm. Or a servo arm outside the keel through a hull bottom slot to the planes.

From reading on here I think that I will use bellows for the servo rods, though so far I haven't discovered where they come from. One of my old aircraft modelling friends said that he used to run in buggy motors in water. I know that a brushless motor will (attempt) to run in water (overturned floatplane) so I wonder if anyone on this forum has experience of running the motor in the wet section? Otherwise I suppose its another sealing problem round the prop shaft. As most surface running boats don't seem to have a leak problem I assume that standard shaft tube seal reasonably well.

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion