The valve is a doddle. Have a look at this..

https://youtu.be/2YsIfgtrXhM

Best John

In total there are 33 users online :: 0 Registered, 0 Hidden and 33 Guests

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Our users have posted a total of 12534 messages in 1992 subjects

We have 1021 registered users

The newest registered user is Mike Echo

Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems Re: Piston Ballast Systems

Re: Piston Ballast Systems

Re: Piston Ballast Systems

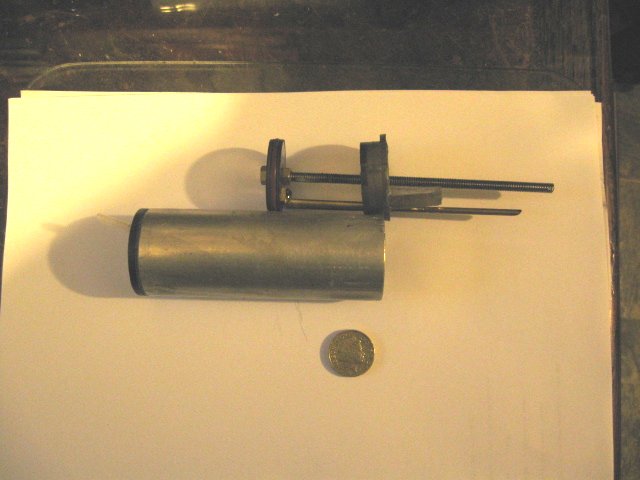

Re: Piston Ballast Systemsdavid f wrote:Just showing my growing collection of DIY piston tanks. The latest one is for the Pioneer. Several have been in use over a number of years. DIY does mean that they can be tailored to fit different hulls. Diameter is the key variable but length is also often a problem.

Sorry about the bins!

David

Re: Piston Ballast Systems

Re: Piston Ballast Systems

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion