Still looking for a how to on the spindle part of the piston.

Who is online?

In total there are 32 users online :: 0 Registered, 0 Hidden and 32 Guests :: 1 Bot

None

Most users ever online was 180 on Tue Nov 05, 2019 6:03 am

Latest topics

Search

Most Viewed Topics

Statistics

Our users have posted a total of 12534 messages in 1992 subjects

We have 1021 registered users

The newest registered user is Mike Echo

Similar topics

+13

tieratus

tattooed

treeboa

profesorul

johnrobinson

ajg141

Hermann

NicK

nigele(ADMIN)2

Tom(ADMIN)

david f

Giovanni LiCalsi

salmon

17 posters

Piston Ballast Systems

salmon- AMS Forum Owner

- Posts : 312

Join date : 2011-09-02

Age : 64

Location : Las Vegas, Nevada - USA

- Post n°51

Re: Piston Ballast Systems

Re: Piston Ballast Systems

I read the book Model Submarine Technology. I have a new appreciation of the delicate art of balancing a submarine.

Still looking for a how to on the spindle part of the piston.

Still looking for a how to on the spindle part of the piston.

salmon- AMS Forum Owner

- Posts : 312

Join date : 2011-09-02

Age : 64

Location : Las Vegas, Nevada - USA

- Post n°52

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Nigel,

950D61 is ordered!

950D61 is ordered!

Last edited by salmon on Fri Nov 18, 2011 11:30 pm; edited 1 time in total (Reason for editing : spelling)

david f- AMS Treasurer

- Posts : 2412

Join date : 2010-11-10

Age : 74

Location : Cumbria

- Post n°53

Re: Piston Ballast Systems

Re: Piston Ballast Systems

I recognise that number. An MFA/Como geared motor.

Good choice Sir!

Good choice Sir!

salmon- AMS Forum Owner

- Posts : 312

Join date : 2011-09-02

Age : 64

Location : Las Vegas, Nevada - USA

- Post n°54

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Yes sir, it is! I asked Nigel for a parts list and he mentioned beginning with this.

salmon- AMS Forum Owner

- Posts : 312

Join date : 2011-09-02

Age : 64

Location : Las Vegas, Nevada - USA

- Post n°55

Re: Piston Ballast Systems

Re: Piston Ballast Systems

sorta bump -

Can anyone help me with building a piston ballast system? Does anyone have a working or broken piston system they want to sell?

Can anyone help me with building a piston ballast system? Does anyone have a working or broken piston system they want to sell?

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°56

PISTON TANK /GEAR BOX.

PISTON TANK /GEAR BOX.

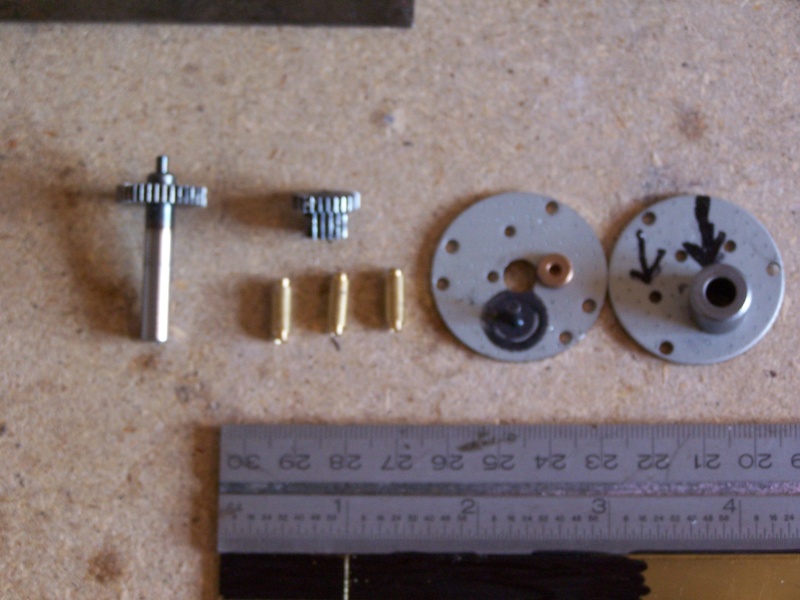

mark up with a felt tip pen a piece of 1/16 x3/4 (approx) brass sheet,take a MFA 950D 6:1 gearbox unit,remove gearbox from motor,mark on the gearbox case as shown all spindle holes that are in use.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°57

Re: Piston Ballast Systems

Re: Piston Ballast Systems

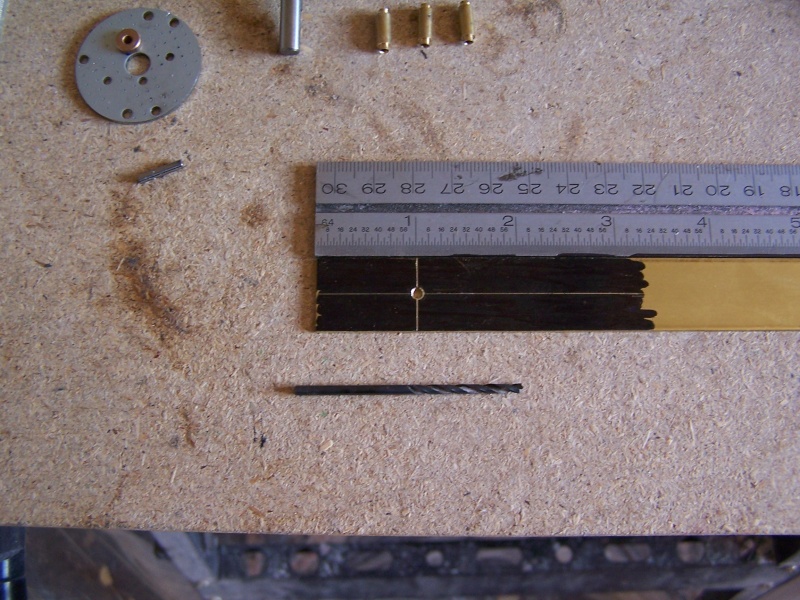

mark a centre line along the brass strip,and then with a square mark a line one inch from the end as shown.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°58

Re: Piston Ballast Systems

Re: Piston Ballast Systems

arrows showing used holes on the drive side of the mfa gearbox.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°59

Re: Piston Ballast Systems

Re: Piston Ballast Systems

arrows showing used holes in rear case of gearbox.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°60

Re: Piston Ballast Systems

Re: Piston Ballast Systems

gentle prise gearbox apart keeping the three brass spacers safe.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°61

Re: Piston Ballast Systems

Re: Piston Ballast Systems

gearbox dissembled,the front case is no longer needed (the one with the large steel bush).

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°62

Re: Piston Ballast Systems

Re: Piston Ballast Systems

rear case with the ideller shaft and bronze bush,this will be used as a drilling template.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°63

Re: Piston Ballast Systems

Re: Piston Ballast Systems

returning back to the brass strip,at the intersection of the two line previously drawn centre pop and drill a 2.5mm hole.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°64

Re: Piston Ballast Systems

Re: Piston Ballast Systems

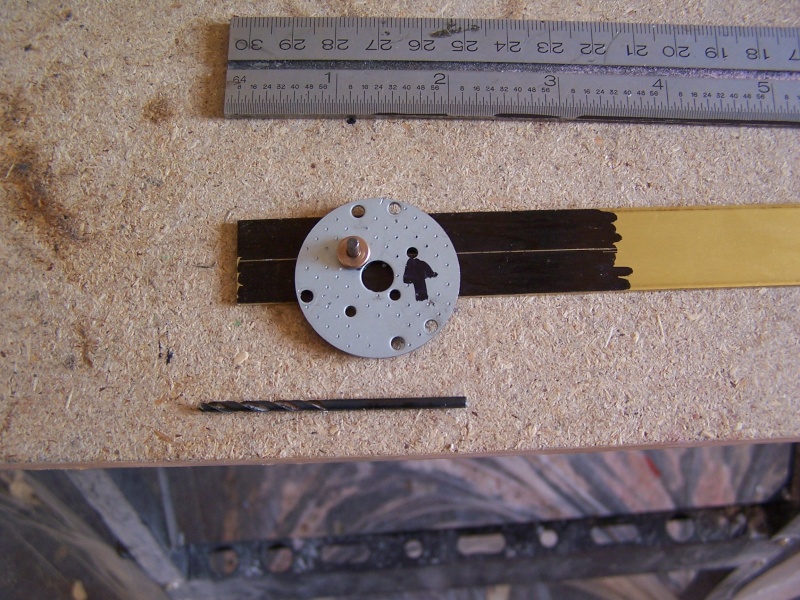

Place the idler shaft in the hole,place the gearbox rear plate on the shaft as shown,drill a second 2.5mm hole using the old gearbox plate as a template (drill through the hole previously marked with an arrow insuring that the hole is on the centre line, I centre pop through the hole just to help keep the drill on the centre line).

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°65

Re: Piston Ballast Systems

Re: Piston Ballast Systems

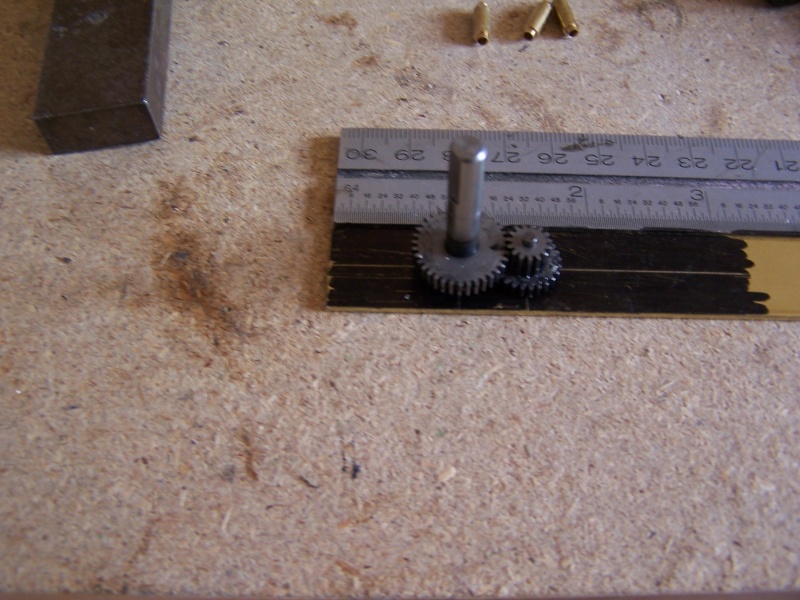

another view

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°66

Re: Piston Ballast Systems

Re: Piston Ballast Systems

the second hole drilled.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°67

Re: Piston Ballast Systems

Re: Piston Ballast Systems

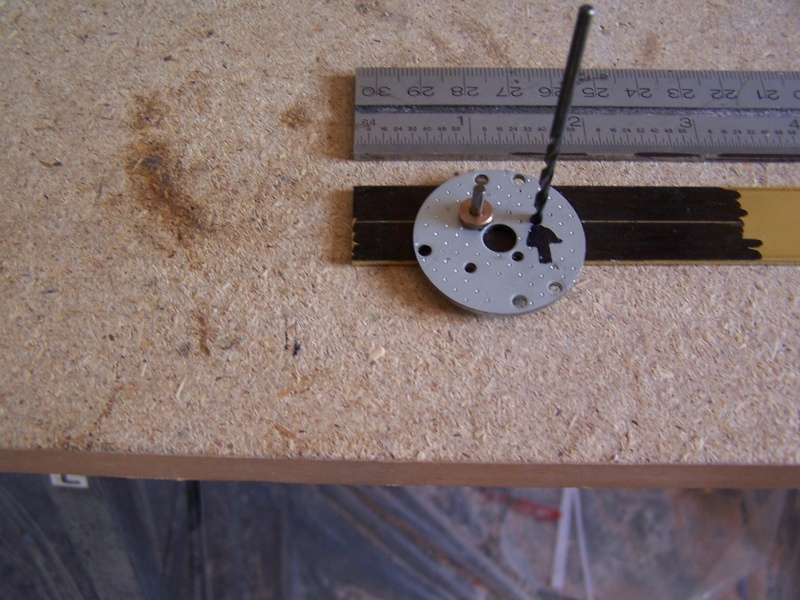

now place the gears on the new gearbox plate and check that the mesh feels ok.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°68

Re: Piston Ballast Systems

Re: Piston Ballast Systems

for the third hole,motor drive messure with a pair of calippers between the ideler shaft hole and the large motor hole on the original gearbox,this needs to be as accurate as poss,but it is ultra crittical.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°69

Re: Piston Ballast Systems

Re: Piston Ballast Systems

now transfer the calipers to the brass gearbox plate mark centre pop and drill another 2.5mm as shown.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°70

Re: Piston Ballast Systems

Re: Piston Ballast Systems

now mark a line and cut of at around three inches,as shown.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°71

Re: Piston Ballast Systems

Re: Piston Ballast Systems

now cut another plate the same as the first.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°72

Re: Piston Ballast Systems

Re: Piston Ballast Systems

as with the first plate mark a hole 1inch from the end drill a 2.5mm hole,put the idler shaft in the hole lay the first plate on top of it clamp together and thansfer all the holes to the second plate.

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°73

Re: Piston Ballast Systems

Re: Piston Ballast Systems

holes transfered to second plate.

salmon- AMS Forum Owner

- Posts : 312

Join date : 2011-09-02

Age : 64

Location : Las Vegas, Nevada - USA

- Post n°74

Re: Piston Ballast Systems

Re: Piston Ballast Systems

Nigel,

Thank you!

This is so exciting!

Peace,

Tom

Thank you!

This is so exciting!

Peace,

Tom

nigele(ADMIN)2- AMS Chairman

- Posts : 1107

Join date : 2010-11-06

Age : 70

Location : Braintree, Essex

- Post n°75

Re: Piston Ballast Systems

Re: Piston Ballast Systems

now take a 4mm dia prop shaft (the dia of the inner shaft),the type with top hat bearing's,knock out the bearings and put the outer shaft aside to be used later,the inner shaft is not used.

drill out the first hole in the gearbox plates to match the bearing dia,in this case it was .250 inch.

» RC Drift Gyro for pitch control

» WW2 mini sub build

» sonar data link

» Robbe Seawolf V2

» ExpressLRS - 868/915 Mhz equipment

» Flight controllers as sub levelers

» 868/915 Mhz as a viable frequency for submarines.

» Microgyro pitch controller corrosion